Was established in

Factory area

Qualifications and Patents

Serve countries and regions

Company, Certification, Production

NINGBO LIDA PNEUMATIC

COMPLETE SETS CO., LTD.

Company is founded in 1994, is professional to provide customers the pneumatic execution, direction control, air source treatment and all kinds of auxiliary services and personalized solutions.

We has been listed as national high-tech enterprises, the national sme technology innovation fund, the national liquid air industry association governing units. LIDING® Brand pneumatic components won Ningbo well-known trademark, and repeatedly been rated as quality trustworthy by product quality supervision department ...

CHARGING

Category

To Provide Better Pneumatic Products For Automatic Equipment Industry

To Provide Better Pneumatic Products For Automatic Equipment Industry

High quality, favorable price, excellent service

View DetailsTo Provide Better Pneumatic Products For Automatic Equipment Industry

To Provide Better Pneumatic Products For Automatic Equipment Industry

High quality, favorable price, excellent service

View DetailsTo Provide Better Pneumatic Products For Automatic Equipment Industry

To Provide Better Pneumatic Products For Automatic Equipment Industry

High quality, favorable price, excellent service

View DetailsTo Provide Better Pneumatic Products For Automatic Equipment Industry

To Provide Better Pneumatic Products For Automatic Equipment Industry

High quality, favorable price, excellent service

View Details

CHARGING

Category

To Provide Better Pneumatic Products For Automatic Equipment Industry

Professional

manufacture

C1

Advanced

Production Equipment

C2

Professional

Qualification Certification

C3

Comprehensive

Service Support

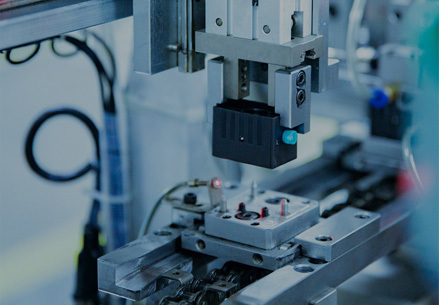

Our company area has 10000 square, and adopted the ISO9001:2015 quality management system certification, the United Kingdom QEC certification and CE certification. Company has professional technical management personnel and the quantity is about one third of the total employees, and set up a lida pneumatic engineering technology research and development center, has formed in the old, middleaged and young inside echelon combination of science and technology.

Learn more

Otherwise,our products has won more than 30 countries registered patents,including 3 invention patents, 20 new utility model. Our products are widely used in knitting, medical, food, packaging,petrochemical, metallurgy. coating, vehicles and other mechanical equipment industry.

Looking forward to providing you with professional services

Learn more

LATEST